two roll mill process of ruber

Latex and two-roll mill processing of thermally-exfoliated

2013年1月24日 Two-roll mill processing was used to disperse thermally expanded graphite oxide (TEGO) into natural rubber (NR). Property improvements achieved by direct milling of TEGO into NR were small and comparable to those provided by carbon black; however, by pre-mixing TEGO with NR latex followed by milling, substantial property enhancements

Rubber Compounding an overview ScienceDirect Topics

Rubber compounding was performed on a two-roll mill (Lab Walzwerk MT 6″×13″, Rubicon, Germany) in a three-stage process. In the first stage, the rubber was mixed with zinc oxide, stearic acid, CB, and Struktol or IPPD. Then the rubber/MLG masterbatch was added to the rubber compound in the second stage.

Grinding of Waste Rubber Rubber Recycling: Challenges

2018年10月3日 Hence, direct recycling, or rather reclamation of rubber, is a difficult process which ends up costing half that of natural or synthetic rubbers. However, The secondary stage converts the coarse waste rubber chips to granular rubber material. The two roll mill is similar to the cracker mill, but it is smaller in size and hence works at a

Rubber Compounding an overview ScienceDirect Topics

Rubber compounding was performed on a two-roll mill (Lab Walzwerk MT 6″×13″, Rubicon, Germany) in a three-stage process. In the first stage, the rubber was mixed with zinc oxide, stearic acid, CB, and Struktol or IPPD. Then the rubber/MLG masterbatch was added to the rubber compound in the second stage.

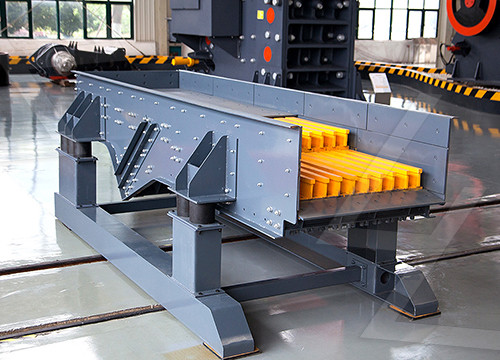

Mixers used in rubber processing: A) two-roll mill and B)

Download scientific diagram Mixers used in rubber processing: A) two-roll mill and B) internal mixer. [34] from publication: Influence of Clay Modification on Curing Kinetics of Natural Rubber

The two-roll plasticiser (TRP) UTH GmbH

2020年3月13日 The two-roll plasticiser (TRP) Processing of rework materials The two-roll plasticiser (TRP)sizes for a larger number ofspecialised tyres, the absolute amount of rework material is increasing worldwide. This creates a need to collect this material in order to be able to re- turn it to the production line by means of a

Introduction to rubber processing and safety issues HSE

2023年4月27日 Fabrication Moulding press Moulding presses Rubber / Process oils1 / Carbon black / Bulk filler2 Internal mixer [Optional] Two roll mill (warming mill / dumping mill) Extruder

2 Compound Processing Characteristics and Testing

2017年7月12日 mixing. Under processingconditions, variousrubber chemicals, ®llers, andother additives canbeaddedandmixedintotherubber toformanuncured``rubber compound.'' These compoundingingredientsaregenerallyaddedtotherubber throughoneoftwobasictypes of mixers, thetworoll mill or theinternal mixer. 2.2.1 TwoRoll Mill